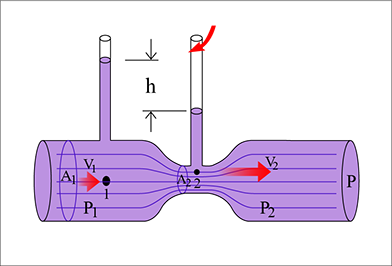

Venturi Principle

SSP Technology

LOTSA has the technology license for using and selling a device named SuperSonic Pump (SSP) which is an Innovative Artificial Lift technology that can be deployed in wells with existing Gas Lift infrastructure.

SSP enables higher oil production in an oil well with same amount or lower Injected Gas.

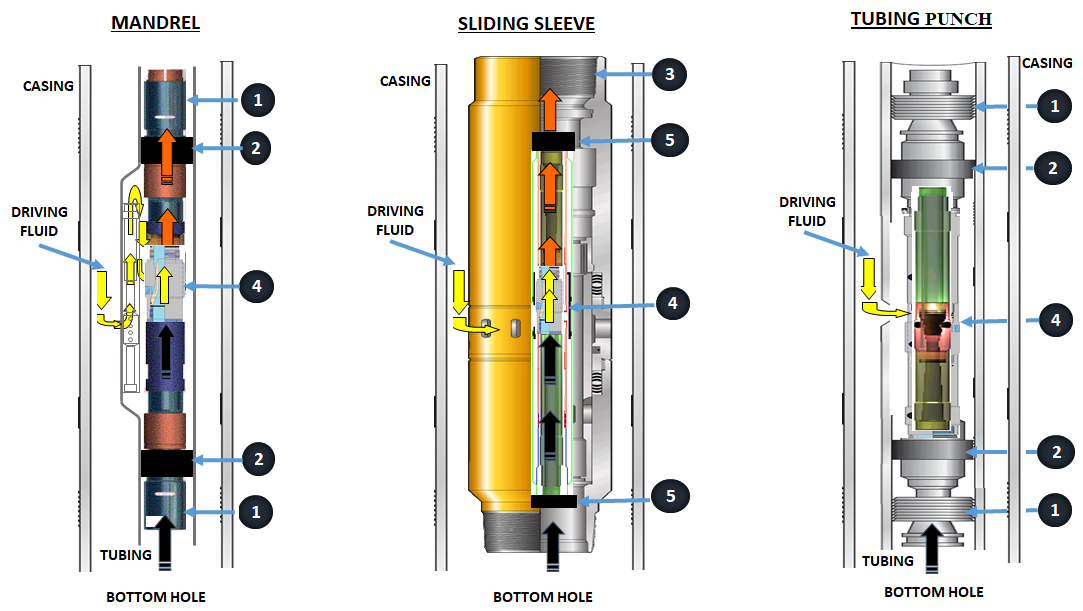

SSP is installed on the tubing production at the level of Mandrel, Tubing Punch or Sliding Sleeve.

Supersonic Pump

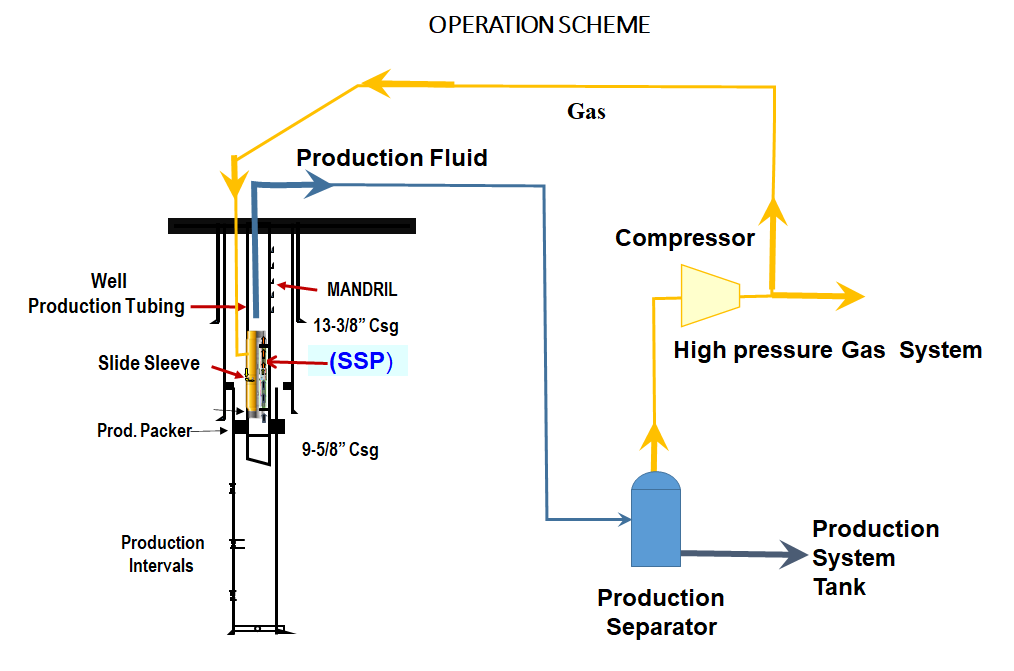

The SSP uses high pressure natural gas as power fluid.

Its efficiency is based on the optimum use the kinetic energy of the power fluid (high pressure natural gas) to generate a sustained suction.

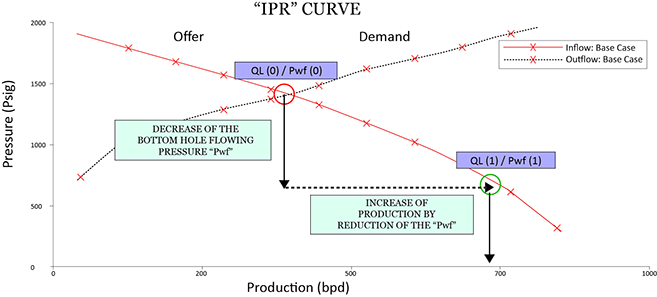

It decreases the bottom hole flowing pressure (Pwf) causing that well production rate increases according to the productivity index.

Supersonic Pump (SSP) Benefits

Benefits Active Owner of Production.

01

Maximize the oil production.

02

Minimize the producer well interventions frequency.

03

Reduces the deferred production.

04

Minimize production costs.

05

Increase Profit.

The SSP originates favorable dynamic and hydraulic conditions for the reduction of the Bottom Hole Flowing Pressure (Pwf), as a consequence, an increase in the Well Production Rate is achieved, as indicated on the IPR Curve.

Supersonic Pump Performance

Supersonic Jet Flow fed with High Pressure Natural Gas as Power Fluid.

SSP combines the benefits of gas-lift systems and hydraulic jet pumps.

As in Gas Lift, SSP decreases the fluid column density but also generates supersonic velocities and sustained suction at the well bottomhole.

SSP reduces the bottomhole flowing Pressure (Pwf) consequently the well production increases according to productivity Index.

Operation Scheme

SSP Installation

Wire line Unit

Well OnShore

Well OffShore

Installations Type

1. Tubing Stop

2. Pack Off

3. Lock Mandrel

4. SSP

5. Seal

United States & Mexico

Fabrication Shop

The fabrication material is selected according to the produced fluid characteristics.

Presence of corrosive and/or abrasive elements H2S, CO2, asphaltenes, sand, others, define the material to be used.

Fabrication Materials

Stainless steel.

Carbon steel ( 4140 and 4340 ).

Tungsten Carbide.

Ceramic Material.

© Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.